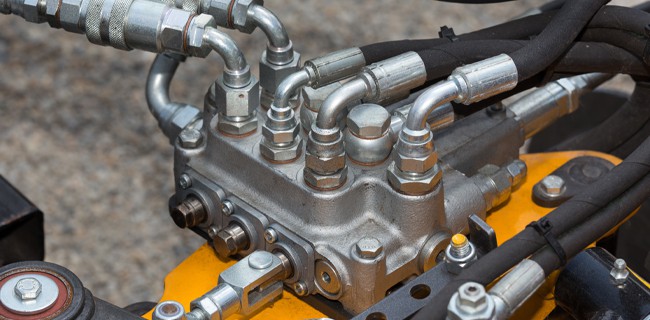

Did you know that 80% of all hydraulic system failures can be attributed to contaminated oil?

It’s true, Power & Motion Magazine says that most hydraulic failures including hoses, tubing, fittings, pump and valve failures can be traced to contaminated hydraulic fluids.

Hydraulic hoses and their fluid can be contaminated from the point of manufacturing down to the end-user. Microscopic particulates enter the assembly and can include:

- Lubricants from the manufacturing process that aren’t cleaned out

- Hose remnants or rubber dust remaining from the cutting process

- Crimping causes metal shards to break off in line

- Unsealed hose ends allow dirt, dust and debris to enter the hose and components

When was the last time you reviewed your hydraulic hose assembly’s cleaning and maintenance plans?

Expensive Side Effects of Hydraulic Line Contamination

The mining industry, for example, demands peak performance from the heavy equipment used to excavate, drill and haul raw materials. Not routinely inspecting, cleaning and maintaining your hydraulic lines and assembly can have a devastating impact on your operations.

Any time your excavators, backhoes or tractors experience downtime, you’re looking at potentially thousands of dollars in lost productivity and revenue.

In fact, a major machinery provider reported that Caterpillar estimates repair idle time due to equipment breakdown can range from 400-800 nonproductive hours per year per machine. When you factor in the operational and repair costs associated with each machine, the loss in revenue is staggering.

Other impacts include:

- Reduction in system efficiency

- Potential catastrophic failure

- Inadequate pump flow or pressure

Think of your heavy equipment’s hydraulic system like our circulatory system. Our bloodlines carry rich oxygenated blood throughout our bodies to fuel and power our cells. Your machinery’s bloodline carries hydraulic fluid to power your equipment. Any dirt, debris or particulate that enters that bloodline has the potential to destroy system components, leaving them vulnerable to premature failure.

Think a little dirt isn’t that big of a deal?

If even a tablespoon of dirt enters a machine’s hydraulic lines, it can pollute the entire system. Once there, it can wreak havoc on all the precision components that help your machine run efficiently.

Can you afford your most critical equipment to go offline?

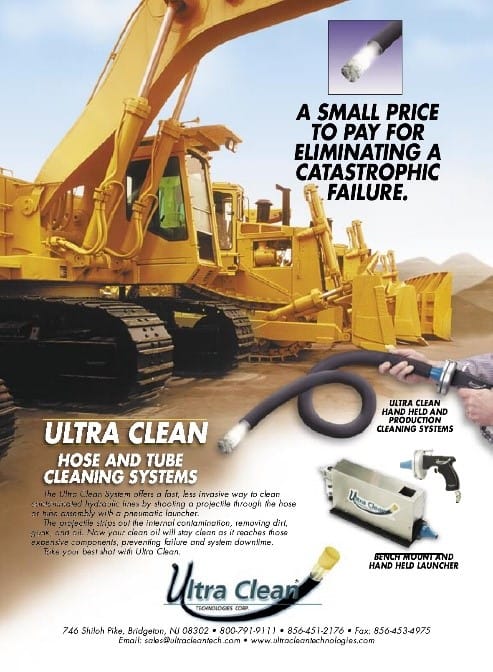

Hydraulic Contamination Control Solutions from Ultra Clean Technologies

We carry innovative hose, tube and pipe cleaning systems that offer a faster and less invasive way to clean contaminated lines and assemblies using pneumatic technology.

It works like this:

- Ultra Clean Projectile pellets are fired through hydraulic lines with the Projectile Launcher.

- Contamination from bending, cutting, crimping or flaring is removed.

- Hose assembly can then be sealed off from debris with the Clean Seal System.

5 Preventative Maintenance Tips to Minimize Hydraulic Line Contamination

Select a clean-cut saw blade.

According to Ultra Clean Technologies, using an abrasive wheeled chop saw to cut the hose to the correct length is the biggest contributor of contamination in a new hydraulic hose line. They recommend choosing a “clean-cut” saw blade designed specifically to reduce contamination.

Use clean, dry air.

Moist, dirty air is the enemy of hydraulic systems and will stick to the inside of hoses and tubing, polluting your equipment’s hydraulic fluid. Ultra Clean recommends using a compressed air dryer that will filter out oils, water and other contaminants that can damage your lines.

Maintain a clean workspace.

A messy, disorganized workspace is full of dirt, grime, debris and airborne particles that love to settle into areas they shouldn’t, especially your hydraulic lines. Schedule routine cleaning and use a vacuum to avoid stirring up contaminants.

Implement the Ultra Clean System. Routine cleaning reduces downtime and the risk of hose failure. The Ultra Clean System uses a machine that fires pellets through the hose assembly to remove rubber dust and metal particles that accumulate during the hose-cutting process. Additionally, it removes contaminated oil from hydraulic hoses, tubes, and pipes. Talk to your Superior Industrial Supply sales rep to purchase a launcher and pellets.

Properly store hydraulic assemblies.

If you are cleaning your assemblies and then storing them on dusty shelves, you’re exposing them to unlimited contaminants. We recommend using heat-shrinkable Clean Seal Capsules from Ultra Clean Tech. We also carry Plastic Caps and Plugs from Caplugs.

Talk to your Superior Industrial Supply sales representative to learn more.

Call 314-638-6500 OPTION 4.

Capping and Storage Solutions for Reduced Hydraulic Contamination

Once your hydraulic systems are properly cleaned, we recommend the use of caps and plugs for the safe storage and transport of hydraulic components. This ensures your hydraulic components will be ready for use when you are, without the damaging effects of contamination from debris or moisture.

Are you looking for alternative hose protection and bundling solutions for your hydraulic systems? We carry a variety of cleaning and maintenance solutions from other top-rated manufacturers like Caplugs. Caplugs is a leading manufacturer of caps, plugs, masking, tubing and netting, hose guards, spiral wraps and more.

No matter your hydraulic hose needs. We have you covered.

Have questions about choosing the right solutions to control hydraulic contamination and protect your lines?

Give us a call at 314-638-6500 OPTION 4.

Superior Industrial Supply understands your hydraulic needs and how regular cleaning and maintenance are critical to your business’s success.

We carry everything you need for your hydraulic systems from top-rated brands like Ultra Clean Technologies and Caplugs. If you have questions on how Superior can help you improve operations and extend the life of hydraulic hose assembly, stop into our St. Louis location, or call 314-638-6500 OPTION 4.