Engineered fluid transfer couplings are devices used to connect and transfer fluids between different components. They are vital in providing a secure and leak-proof connection while still allowing for efficient disconnection when necessary. A major function of engineered fluid transfer couplings is to prevent accidental disconnection, depressurization and fluid release during operation or during pull-away incidents.

These couplings are commonly used in industries that require the transfer of various types of fluids (both hazardous and non-hazardous) and include automotive, aerospace, food and beverage, manufacturing, marine, oil and gas and pharmaceuticals.

Each fluid transfer coupling must be carefully chosen based on the application, type of transferred fluid, material compatibility, pressure and temperature ratings, as well as hygienic and environmental requirements.

Some examples of engineered fluid transfer couplings include:

- Special dry disconnect couplings

- Industrial / marine break-away couplings

- Rupture discs

Which one is right for your needs? To help you choose the best option, we explain some of the top features and benefits of commonly used couplings from our partner, Dixon Valve.

What do special dry disconnect couplings do?

Special dry disconnect couplings are also known as quick disconnect couplings or dry break couplings. Special dry disconnect couplings are designed to provide a secure and leak-free connection between pipes or hoses. These couplings have internal valves that close automatically when disconnected, preventing the release of fluids and minimizing the risk of depressurization and potential hazards.

Dry disconnect couplings are widely used in industries such as oil and gas, chemical processing, pharmaceuticals, and food and beverage. They are particularly useful in applications where the transfer of hazardous or valuable fluids occurs, and the prevention of spills or leaks is crucial. They are often used by producers of:

- Adhesives

- Agriculture

- Chemicals

- Caustic substances and acids

- Ink

- Petroleum

- Pharmaceuticals

By ensuring a sealed connection during both connection and disconnection processes, dry disconnect couplings help maintain system integrity and protect personnel and the environment.

Have questions on improving the reliability and life of your

industrial hoses?

Call 314-638-6500 OPTION 4 or toll-free 800-783-6501

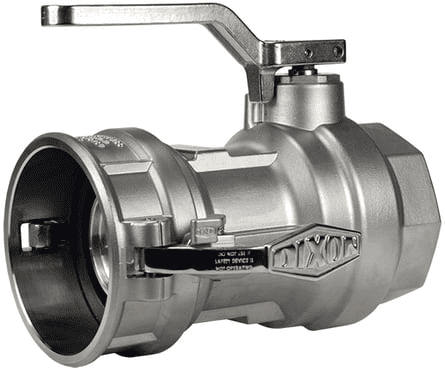

Dry Disconnect Solutions from Dixon Valve®

Bayloc Dry Disconnect Coupler

The Bayloc dry disconnect coupler is compatible with most cam and groove style dry disconnects and helps prevent spillage from normal or accidental disconnects. A spring-loaded sealing device is designed to “snap” closed in the event the valve is disconnected with the poppet open to significantly limit liquid loss.

Watch now: Bayloc® Dry Disconnect

Bayonet Dry Disconnect Coupler

The Bayonet dry disconnect coupler is ideal for use in fuel and lube oil service industry and offers a maximum pressure rating for fittings of 85 PSI at 70° F (21°C). The Bayonet is compatible with Emco Wheaton™ Dry Break™.

Dixon MannTek Dry Disconnect Coupler

The Dixon MannTek dry disconnect coupler is often used in applications that require extra care such as handling toxic chemicals or fuels, or for transferring clean water. There are also design adaptations specifically for use with dry aviation or dry gas transfer.

Compare Dry Disconnects from Dixon Valve.

What are industrial safety break-away couplings?

Industrial safety break-away couplings are designed to minimize spillage and damage that may occur with drive away and pull away incidents. Think: Loading racks.

They are designed to be installed between a fixed point (pipe, pump, manifold) and a hose.

Here’s how it works: The industrial safety break-away coupling is made of two halves, each of which have a valve with an O-ring seal. The coupling will sense an excessive load, close the valves and disconnect. This important feature minimizes fluid exposure to individuals, equipment and the environment.

Marine safety break-away couplings are another option for reducing spillage and damage associated with pull-away incidents. While they have the same internal mechanisms as an industrial break-away coupling, they are different in that they have additional external features that offer increased resistance to torsional and bending moment forces that may be present in unpredictable marine environments. They are also designed to be installed within a hose string where a coupling will have a length of hose attached to both sides.

Additionally, some safety break-away couplings have breaking bolts. When there is axial tension, three bolts take up the force corresponding to the break force on the hose. In the event of non-axial forces, it will concentrate the tension more onto one bolt, so the safety break-away coupling reacts to the hose break forces.

Note: Break loads for bolts should be based on the specifications of each application.

Download Safety Break-Away Checklist from Dixon Valve

What are rupture discs?

Rupture discs, also referred to as burst couplings or bursting discs, are designed to relieve excess pressure in a system by bursting or rupturing at a predetermined pressure threshold. These devices are typically installed in pipelines or vessels where the pressure can exceed safe operating limits, posing a risk to equipment and personnel.

When the pressure inside the system reaches the predetermined level, the burst coupling fails at a weakened point, allowing the excess pressure to be safely released. This prevents catastrophic failures, such as explosions or structural damage, that could occur if the pressure continued to rise unchecked.

Burst couplings are commonly used in industries such as chemical processing, oil and gas, power generation, and manufacturing, where high-pressure systems are present. They serve as a safety measure to protect equipment, prevent over-pressurization, and eliminate the risk of depressurization-related accidents.

Download Dixon Valve Dry Disconnects and Breakaways

To prevent accidental discharge from pull-away incidents, you have many choices and it can quickly become confusing. Rely on your Superior Industrial Supply team to get straightforward advice on your most challenging job-related issues.

Give us a call at 314-638-6500 OPTION 4 or toll-free 800-783-6501 and speak to a knowledgeable representative today!

Superior Industrial Supply knows how important it is to have access to the industrial hoses, disconnect couplings and the fittings your operations demand. It’s why we specialize in hose assembly and repairs, as well as industrial and MRO supply and fastener selection for the St. Louis region and beyond.

We carry everything you need for your industrial hose assemblies from top-rated brands like Dixon Valve. Give us a call at 314-638-6500 OPTION 4 or 800-783-6501 and let us know how we can help you find the products, services and advice you need.