Want to design a more reliable hydraulic hose assembly?

Choosing the right components at the start ensures a secure and leak-free hydraulic connection. You may not realize this, but making sure the threads and material of your adapters and fittings match is just as important as selecting the right hose for your application.

Let’s talk about it.

What is the Difference Between Hydraulic Adapters and Hydraulic Fittings?

The terms fitting and adapter are often used interchangeably when discussing a hydraulic hose assembly. However, they are not the same.

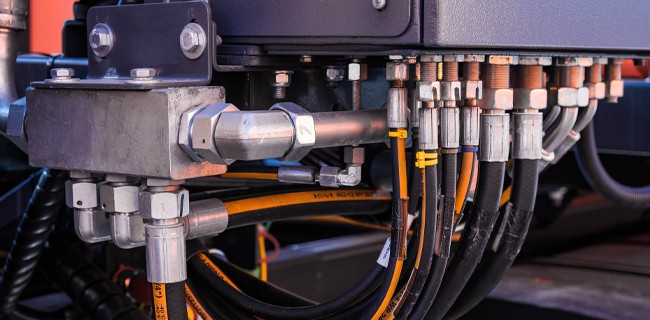

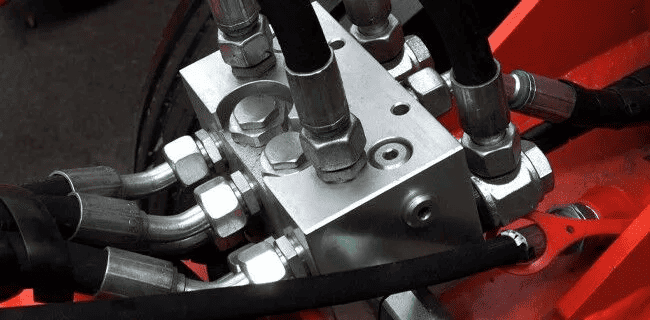

Hydraulic fittings allow hoses and tubes to be plumbed and connected to pumps, motors, valves and cylinders. Most fittings have a male end and a female end that join to form a connection. Fittings allow for easy installation and removal in the event of damage or wear — it’s easier to change out a fitting than an entire hose. Hydraulic fittings are often made from forged and/or machined steel to be strong and rigid.

Hydraulic fittings are the weakest link in your hose assembly and must be chosen with care to prevent leaks and maintain pressure.

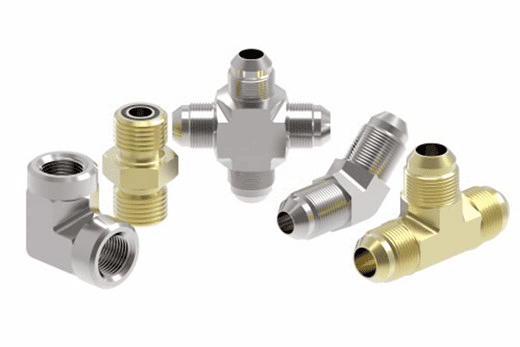

Hydraulic adapters allow the connection of two different components that normally would not be compatible and can be made from aluminum, steel, stainless steel or brass. Sometimes, adapters can be used as a fitting, but their inherent function is much more complex.

Adapters are often used to connect components with different-sized threads or to interchange competing component standards such as:

- SAE (Society of Automotive Engineers)

- JIC (Joint Industrial Conference Fittings)

- NPT (National Pipe Threads Fittings)

- Metric

Explore common types of end connection fittings.

Have questions on improving the reliability and life of your hydraulic systems? Call 314-638-6500 OPTION 4 or toll free 800-783-6501

When Do I Need an Adapter for my Hydraulic Hose Assembly?

Hydraulic adapters come in many shapes and sizes and can be used in endless applications for manufacturing, construction, automotive and marine markets. Hydraulic adapters can have different configurations including:

- Male-to-male

- Female-to-female

- Male-to-female

Whereas fittings are usually used to connect hoses and tubes, adapters enable creative solutions for hydraulic hose assembly. For instance, maybe you have a hydraulic hose that requires a tee adapter, or you need to add a pressure gauge to the assembly.

However, to properly connect different hydraulic hose components, you first need to understand the concept of proprietary fit.

What is Proprietary Fit?

In the article, Making Sense of Hydraulic Hose Standards, Power & Motion magazine says hydraulic hose construction and performance are covered by national and international standards including:

- ISO (International Standard for Organization)

- BSI (British Standards Institution)

- SAE (Society of Automotive Engineers)

- DIN (German Institute for Standardization)

- API (American Petroleum Institute)

- CETOP (European Fluid Power Committee)

Most proprietary hoses conform to one standard or another, the SAE standards being the most widely followed in the U.S.

SAE standards provide general, dimensional and performance specifications for the most common hoses used in hydraulic systems on mobile and stationary equipment.

Why is this important?

Because mixing and matching components from different manufacturers can result in an improper fit, and subsequently, a failed hose assembly. This is why a proprietary fit is usually the best fit.

6 Tips for Choosing the Right Hydraulic Hose Adapters

There are instances when you will have to create a hose assembly from various components. Not only should your hose match the application, but the threads of your fittings and adapters should as well because each connection point is a potential leak point.

1. Identify hose specifications.

Ask yourself these questions: What size hose will you be using? What type of hose does the job require? How much pressure does your hose need to handle? What are the temperature requirements?

2. Decide adapter requirements.

Evaluate your hydraulic system to determine what adapters and fittings will be required and consider the standards your application must adhere to for compliance, performance and safety.

You’ll want to determine the thread type you need based on the existing system. Common thread types include NPT (National Pipe Tapered), BSPP (British Standard Pipe Parallel), BSPT (British Standard Pipe Tapered), JIC (Joint Industry Council), ORB (O-Ring Boss) and ORFS (O-Ring Face Seal) and metric threads.

3. Match hose and adapter specs.

Determine if your chosen hose and adapter configuration are compatible with one another. Consider the thread and size requirements of that configuration and the pressure ratings of the system.

4. Check material compatibility.

Adapters and fittings can be made from various materials that have different degrees of durability and resistance to corrosion, pressure or temperature demands. Make sure you choose the materials designed specifically for the conditions and environment of the application.

5. Consider the sealing method.

What kind of seals does your assembly require? Different adapters use different sealing methods such as O-rings, cone seals or metal-to-metal. Choose the seal best for the application to prevent leaks and improve functionality.

6. Contact a Superior Industrial Supply rep.

Trying to design a new hydraulic hose assembly or still have questions about an existing system? Speak to one of our hydraulic experts for further guidance on your specific needs and application.

We Recommend Danfoss Precision-Machined Adapters for the Perfect Fit on Hydraulic Assembly

Source: Danfoss

Need hydraulic adapters that can adapt to your biggest application challenges?

For fluid conveyance in your hydraulic systems, we recommend Danfoss precision-machined adapters. They are available in a wide range of sizes and three material options that include carbon steel, stainless steel and brass, making them ideal for a variety of applications. Top features of the Danfoss adapter line include:

- Dura-Kote plating: Superior corrosion resistance up to 1,000 hours

- Design flexibility: Thousands of styles to choose from

- Higher operating pressures: Above SAE standards

Use Danfoss Cross-Reference Tool

Give us a call at 314-638-6500 OPTION 4 or toll free 800-783-6501 and speak to a knowledgeable representative today!

Superior Industrial Supply knows how important it is to have access to the hydraulic hoses, adapters and fittings your operations demand. It’s why we specialize in hydraulic hose assembly and repairs, as well as industrial and MRO supply and fastener selection for the St. Louis region and beyond.

We carry everything you need for your hydraulic hose assemblies from top-rated brands like Danfoss Power Solutions. Give us a call at 314-638-6500 OPTION 4 or toll free at 800-783-6501 and let us know how we can help you find the products, services and advice you need.