For high-yield and high-production applications like agriculture or farming, you demand tough and durable industrial hoses that withstand harsh environmental conditions.

Industrial hoses are an integral part of many equipment systems but tend to receive the least consideration compared to other important components. The truth is, a worn-out hose can be just as problematic as a failed pump or electronic system, leading to pressure bursts, slip-and-fall accidents, chemical burns and risks to crops and the environment.

For this reason, we recommend choosing industrial hoses built to last and suited to the job they must perform. Are you looking for any of the following industrial hose options:

- Hoses for maintenance

- Hoses for spraying

- Irrigation hoses

- Fertilizing hoses

- Hoses for cleaning

- Hoses for pesticides and chemicals

- Water transfer hoses

- Air service hoses

- Slurry suction and discharge hoses

Whatever your industrial hose needs, we have you covered with hoses and fittings designed to resist chemicals, abrasion and the elements.

Have questions on improving the reliability and life of your agriculture or farm hoses? Call 314-638-6500 OPTION 4 or toll-free 800-783-6501

Reliable Agricultural Industrial Hoses from Boston by Danfoss

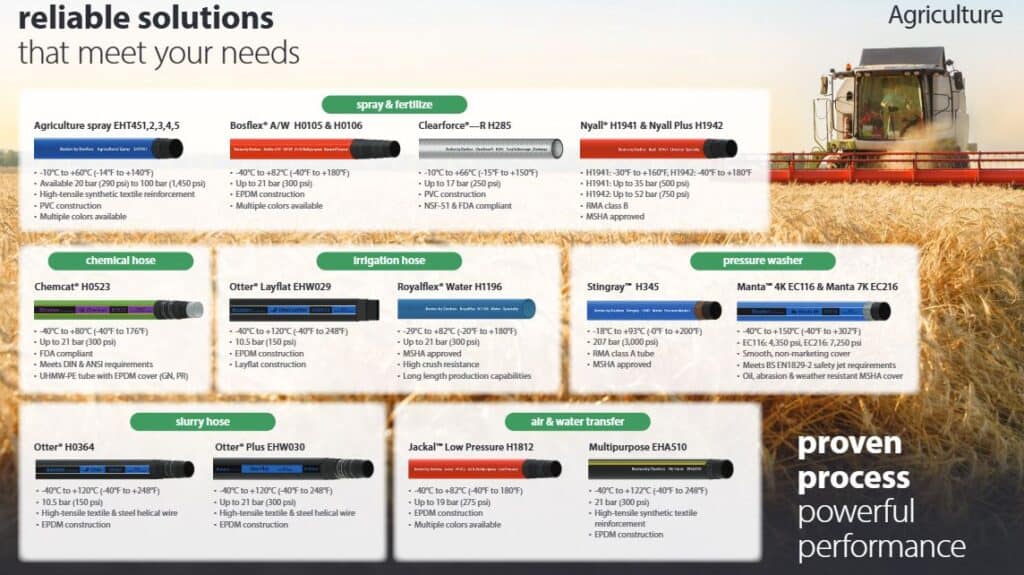

Our partnership with Danfoss, formerly Eaton, means you have access to the widest selection of industrial, specialty and hydraulic hoses, along with the fittings and connectors designed for applications involving:

- Spray & Fertilize

- Air & Water Transfer

- Chemical

- Irrigation

- Pressure Washing

- Slurry

Here’s why we trust Danfoss for our agricultural customers:

Danfoss industrial hoses come from a long line of innovation and excellence, plus they have the fittings, tubing and connectors you need for leak-free assembly. They also specialize in:

- Industrial Hoses

- Fuel, Air Conditioning, Thermoplastic and Specialty Hoses

- Connectors

- Hydraulic Hoses and Fittings

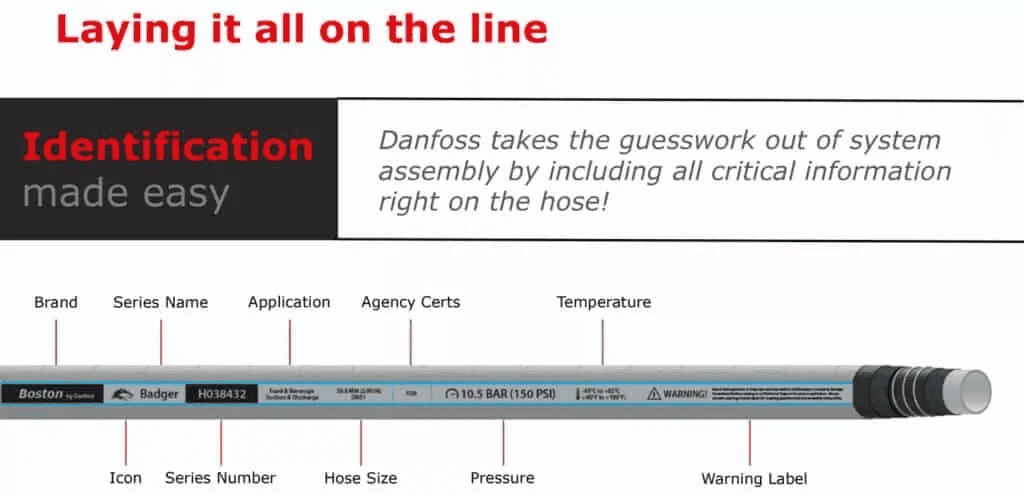

And… Danfoss recently upgraded their hose line-up to include the time-tested Boston brand that makes hose selection pain-free with:

- Easier Identification

- Standardized Market Color Schemes for Consistency Across Industries

- Boston Icons for Enhanced Recognition

Learn more about Boston by Danfoss.

What to Consider When Choosing Agricultural Hoses

Choosing the right industrial hose for your agricultural or farming needs can be challenging, especially when determining material, safety and performance requirements. But it pays to spend time on the front end evaluating your hose assembly needs instead of costly repairs on the back end.

Of course, we recommend following industry standards and regulatory requirements when designing your hose assembly. But don’t overlook these factors either:

- Does the application require a flame-resistant or flame-retardant hose?

- Does the application require low-pressure or high-pressure components?

- Does the application have flexibility or routing requirements?

- Does the application require UV resistance?

- What material will be conveyed?

- Will the hose be exposed to corrosive elements?

- Will the hose be exposed to extreme temperatures or conditions?

The acronym STAMPED — Size, Temperature, Application, Media, Pressure, End and Delivery — can help you choose the hoses and fittings for your needs.

S (Size)

Consider the outside diameter of your hose and wall thickness to reduce pressure loss and maintain proper flow.

T (Temperature)

Consider the hose’s average, minimum and maximum operating temperature ranges when choosing various hose fitting materials and seals like O-rings. Be sure to consider factors such as flame resistance as well.

A (Application)

Will there be excessive abrasion, vibration, unusual mechanical loads or exposure to external conditions such as moisture, salt water, fertilizer, oxygen, oil, acids or chemicals? Choose coatings and special platings for your fittings that can minimize corrosion or breakdown of the fitting.

M (Material)

What kind of fluid will be carried through your hose? Special materials require specialized hose materials and fitting components compatible with the fluid being used.

P (Pressure)

Consider your system’s average operating pressures and its compatibility with the maximum pressures associated with your hose assembly.

E (Ends)

What kind of end is required to connect hoses to the system? Remember that these areas are the weakest link in your hose assembly, and having this information will help you identify the proper fitting and clamping systems to use.

D (Delivery)

Consider any job-related requirements for testing and certification. Once a new hose assembly has been put into service, it’s also important to fully inspect regularly and look for worn-out fittings, clamps or damaged hoses.

To make selection even easier, we created a free form you can print out.

What Materials are Right for Agricultural Hoses?

The term “industrial hose” may suggest hoses are designed to be durable enough to withstand industrial applications. And in most cases, it does. For more demanding or complex applications, industrial hoses typically demonstrate greater durability and flexibility.

However, industrial hoses have strict material requirements for safety and performance compared to other uses when working in agricultural or farming environments.

Here are just a few examples of materials commonly used in agricultural hoses and what makes them unique:

PVC (polyvinyl chloride) is an affordable option for low-volume, light-duty applications such as ventilation or light dust extraction.

Thermoplastic Rubber offers flexibility and resistance to chemicals, as well as a wide range of temperature limits making them ideal for transferring materials or exhausting fumes, dust and vapors.

Polyurethane offers increased chemical resistance, abrasion resistance and weathering resistance over their PVC and thermoplastic rubber counterparts. As a result, they are ideal for heavy-duty agricultural applications, as well as manufacturing, mining and lumber.

Polyethylene is ideal for use in high-velocity, water-feeding, sewage or vacuum systems as it is lightweight, flexible and resistant to acids and UV.

Other materials used in industrial hose construction may include:

- Composite

- Neoprene

- Silicone

Need Service or Help Designing a Hose Assembly? Give us a call at 314-638-6500 OPTION 4 or toll-free 800-783-6501 and speak to a knowledgeable representative today!

HOW TO INSPECT FOR WEAR POINTS ON YOUR INDUSTRIAL HOSE

Even with the best industrial hose material on the market, there’s no guarantee how long your hose will last. The only thing that is certain is that they will fail at some point. The only question is when. Failure to regularly inspect and maintain hose assembly can be costly and dangerous but a few simple steps can extend the performance of your hose and equipment.

Follow these 3 hose maintenance inspection tips for longer service life:

- Visually Inspect Equipment Daily Before Starting Equipment

- Visually Inspect Couplings, Clamps and Fittings

- Visually Inspect Equipment During Off-Season

Learn to spot the signs of industrial hose fatigue.

Superior is your industrial hose distributor for the St. Louis region. We understand having a hose fail onsite can quickly halt production. We carry everything you need for industrial hose assemblies from top-rated brands like Danfoss Power Solutions.

If you have questions on how Superior can help you improve operations and extend the life of your industrial hose assemblies, stop into our St. Louis location or call 314-638-6500 OPTION 4.