Supply constraints throughout the COVID-19 pandemic and recovery phase have caused prices to skyrocket. Not only is the marketplace struggling to keep products on the shelves, but access to raw materials has also dwindled, making it harder to manufacture goods on time and on budget. Managing your supply chain is harder than ever and you need solutions that can save you time and money.

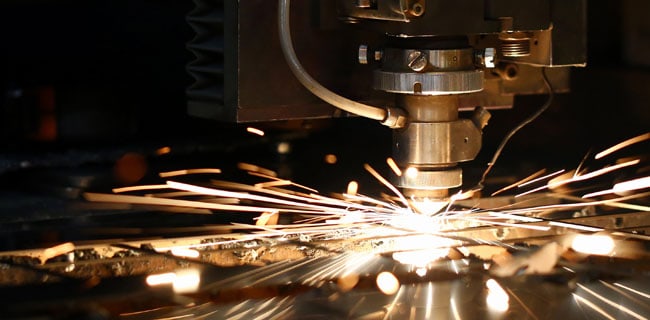

For superior metal cutting performance in industries and applications like metal fabrication, manufacturing, facility maintenance, shipbuilding and more, you need tools you can count on. In addition to size, style and abrasive grain selection, the condition of your cutting wheels can make or break your efficiency and results — not to mention your budget.

Do you recognize these common metal cutting problems?

- Short Wheel Life

- Edge Glazing

- Arbor Hole Damage

- Damaged Edges

If you’re looking for a way to save on tooling and equipment costs, your cutting wheel’s performance is a great place to start. Check out this video for tips on selecting the right Weiler abrasives for your needs.

Watch Now: Selecting Cutting, Grinding & Combo Wheels

Have questions on improving your metal cutting operations?

Give us a call at 314-638-6500 OPTION 4.

Improve Metal Cutting Efficiency: Money-Saving Solutions for 4 Common Cutting Wheel Problems

As supply costs rise amid supply shortages and shipment delays, we wanted to offer some strategies that can help you avoid unexpected costs from your metal cutting tools. We share tips from industry-leading abrasives expert, Weiler Abrasives, on how you can start saving money and achieving better cost-per-cut.

Short Wheel Life

Does it seem like you are changing out cutting wheels more frequently than you would like? Cutting wheel life can be impacted by several factors and addressing them can save you time and money. Are you guilty of the following actions?

Excessive Pressure

Are you applying too much pressure on the cutting surface? Too much can weaken the wheel’s structure, causing it to break down more quickly. Instead, opt for moderate pressure for faster and more accurate cutting action.

Inadequate Torque

On ceramic grains, using an underpowered tool can cause you to change out cutting wheels more often. Ceramic grains need adequate torque and power to break down the grain and create a sharp cutting surface. Check your tool speed and torque to make sure it is offering the right amount of power and let the grains do the work.

Ignoring Storage and Shelf Life

You may be surprised to learn that abrasives like cutting tools have an expiration date. That is because the adhesive used to hold the wheel together only lasts for so long. That said, proper storage of your cutting wheel can extend the life and performance of your tool. Be sure to check the manufacturer’s recommendations for tips on storage and tool life.

WEILER PRO TIP: Did you know that power cords designed for home use can choke out the power going to your tool? Be sure to use industrial-grade extension cords of at least 10- or 12-gauge. Pick up more metal cutting tips from industry expert Weiler Abrasives here.

Edge Glazing

For effective cutting capability, the cutting wheel must be in optimum condition. It’s important to inspect the wheel for glazing or loading before use. A glazed edge is when the abrasives become dull and loading is when foreign matter gets trapped in the spaces between the abrasive grit. Both can impact the resulting surface finish as well as cutting time. Evaluate your current application to determine if the following actions are causing edge glazing or loading:

- Using a product that is too hard for the substrate

- Not using enough motion through the cut

- Not applying adequate pressure

Arbor Hole Damage

The arbor hole serves a significant purpose in the mechanics of the cutting wheel. Damage to the arbor hole can negatively affect the security of the fit, leading to slippage. Reasons for arbor hole damage include:

- Excessive pressure

- Excessive sideload

- Improper clamping of the workpiece

- Product binding and vibration

- Improper mounting

Damaged Edges

Any damage to your cutting wheel can result in increased cutting time, slowed production and diminished surface finish. Be sure to check for damage to the wheel itself as well as its compatible tooling. If in doubt, do a test run to check for imbalance, vibration or chunking that is common with edge damage. Cutting wheels can sustain damage due to the following:

- Improperly clamped workpieces

- Cutting too far away from the clamp

- Performing actions not recommended (ex: grinding with a cutting wheel is a no-no)

Want to learn how Superior can help with fast turnaround times, competitive pricing and extensive product knowledge? Read our customer success story.

Give us a call at 314-638-6500 OPTION 4 and speak to a knowledgeable representative today!

Superior Industrial Supply knows how important it is to have durable and reliable equipment for your most demanding applications. That’s why we partner with top-rated suppliers like Weiler Abrasives. Give us a call at 314-638-6500 OPTION 4 or 800-783-6501 and let us know how we can help you find the products, services and advice you need to do just that.

Don’t forget to visit our website or read our blog for more information!