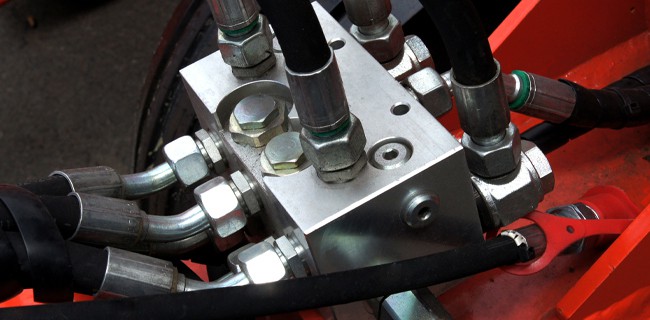

Hydraulic hoses on heavy equipment like bulldozers and excavators are exposed to harsh conditions, vibration, extreme cold or heat, chemicals and repeated strain (to name a few).

When the hoses and fittings on that equipment aren’t routinely examined for wear and tear, your operation runs the risk of equipment failure. The mess, environmental damage, fines and operational costs are enough to wreak havoc on your business, let alone the risk of injury to your workers.

We know it’s far too easy to overlook your hose assembly needs until it’s too late. You have a lot on your mind, and hoses, fittings and connections probably aren’t always on your radar.

Don’t worry. We are here to help. We’ll teach you how to spot the warning signs of a failing assembly and provide you with expert strategies to eliminate unnecessary machine downtime and keep your employees safe.

Why Do Hydraulic Hoses Fail?

Leaks, pressure surges and system failures are all unwanted side effects of hose neglect. But what’s the biggest culprit? How do I know my hydraulic system is going bad? One noticeable sign is when your equipment seems to be running louder than usual. Other signs of potential hydraulic hose failure may include:

- Abnormal noises

- High fluid temperatures

- Slow or erratic operation

Aside from normal wear and tear, hose failure can result from a myriad of factors including contamination during the assembly process, incorrect installation, material fatigue and external damage. Other common causes include:

- Abrasion

- Poor routing

- Improper bend radius

- High temperatures

- Fluid incompatibility

- Contaminated or clogged lines

Other times, the root cause of hose failure may be simply using the wrong style of hoses, adapters or fittings.

Want to design a more reliable hydraulic hose assembly?

When in doubt, we recommend consulting with a hydraulic expert that can evaluate your needs and provide tailored assembly recommendations.

Have questions on improving the reliability and life of your hydraulic systems? Call 314-638-6500 OPTION 4 or toll free 800-783-6501

How to Avoid Hose Assembly Failure in the First Place

When you incorporate planned preventative maintenance into your schedule, not only will you have higher production output and improved safety, but you’ll also experience benefits like lower operating costs, predictable maintenance and repair costs, and reduced environmental impact.

To avoid hose failure, we recommend:

- Only using components designed to work together.

- Properly storing unused hose components to prevent contamination and degradation.

- Inspecting equipment (and yes, hose assemblies daily) before starting and routinely throughout.

- Inspect couplings, clamps and fittings daily.

- Never exceed manufacturer’s maximum hose pressure recommendations.

- Employ experienced professionals when replacing hoses used to convey steam, chemicals and flammable or high-pressure materials.

- Use protective covers and clamps to improve safety and extend hose life.

- Use proper PPE and safety equipment.

NOTE: This is not an exhaustive list of service and maintenance recommendations. Always refer to the manufacturer’s guidelines for proper hose handling procedures and contact Superior Industrial Supply for all your hose needs and hose-related questions.

Did you know that 80% of all hydraulic system failures can be attributed to contaminated oil? It’s true. Our pals over at Power & Motion Magazine say most hydraulic failures are due to contaminated hydraulic fluid. We’ve got a solution for that too. Go ahead and check out our tips for controlling contamination in your hydraulic lines.

Protective Hose Solutions to Extend Service Life and Performance

In your business, you can’t avoid all hose failure. But you can prevent it with a few simple preventative solutions.

Protective hose covers, sleeves and shields not only reduce the likelihood of premature wear but can also protect your people and operation from catastrophic failure. Here are a few examples:

Abrasion Sleeves: Abrasion-resistant covers protect hoses from degradation from friction that occurs over time. Usually made from lightweight urethane, abrasion sleeves allow hoses to move freely and protect against damage resulting from rubbing against themselves and other system components.

Clamps: For general work-holding needs, clamps are available in endless variations to minimize stress, movement and damage. Whether you need reusable clamping devices or economical one-and-done versions, there is a clamp to help you ensure an effective and secure connection and reduce unwanted movement.

End Connections: If your hydraulic systems are exposed to high temperatures, high pressure or high levels of abrasion, there are end connection fittings made specifically for those applications.

Other protective solutions include:

- Fire sleeves

- Spring or spiral guards

- Protective covers

- Hose shields

- Reinforcement layers

Learn other ways to protect your hydraulic hose for longer service life.

Troubleshooting Beyond the Sale

One Superior customer had a hydraulic hose for a pressure washer that conveyed hot water. The team had been experiencing ongoing hose failure and wanted a better, safer solution. After consulting with the customer, we learned the point of failure was due to an unnecessary swivel fitting with a nylon gasket that broke down under hot water pressure. We changed it to a two-piece fitting made of more durable materials that would not degrade under the conditions.

Our Partner for Reliable and Secure Mobile Hose Replacement 24/7

If you have ever had a hydraulic hose burst on site, you know how time-consuming it can be to locate someone to repair that hose assembly quickly and effectively. In remote locations, or during second or third shifts, waiting for that hose replacement can take hours, if not days.

If you don’t have the capability to fix it yourself, it can become a very expensive problem. When missed deadlines and equipment downtime isn’t an option, we have you covered.

“Rich Italiano helped us create a hose making station where we can internally make hoses for our machines, or fork trucks. He’s been very helpful with whatever we need, whether it’s hand tools or supplies. If he can’t get it for us, he leads us in the direction to get it. He’s honest and a good guy to work with.” — Maintenance Planner, Motor and Generator Manufacturer.

For companies that run heavy equipment regularly, we can place a hose crimping machine onsite, complete with bulk hose and hose ends. We also offer thorough training for fast and effective hose repair when you need it most.

Superior Industrial Supply has partnered with JCH Hose and Fittings, mobile hydraulic and industrial hose service provider, to ensure you:

- Get back up and going fast. And if it’s a weekend, you won’t have to wait until Monday.

- A stress-free experience. Our technician comes to you, assesses your needs, fixes it and tests it. We take care of the problem; you keep working.

With more than two decades of experience, the JCH Hose and Fittings team is also certified by the Mine Safety & Health Administration. They are also members of Operating Engineers Local 513 (Union).

Need Service? Give us a call at 314-638-6500 OPTION 4 or toll free 800-783-6501 and speak to a knowledgeable representative today!

Superior Industrial Supply knows how important it is to have access to the hydraulic hoses, adapters and fittings your operations demand. It’s why we specialize in hydraulic hose assembly and repairs, as well as industrial and MRO supply and fastener selection for the St. Louis region and beyond.

We carry everything you need for your hydraulic hose assemblies from top-rated brands like Danfoss Power Solutions. Give us a call at 314-638-6500 OPTION 4 or toll free at 800-783-6501 and let us know how we can help you find the products, services and advice you need.

Have A Parker or Gates Hydraulic Hose Crimper onsite but want to run Danfoss Hoses? We’ve got you covered. Learn more.