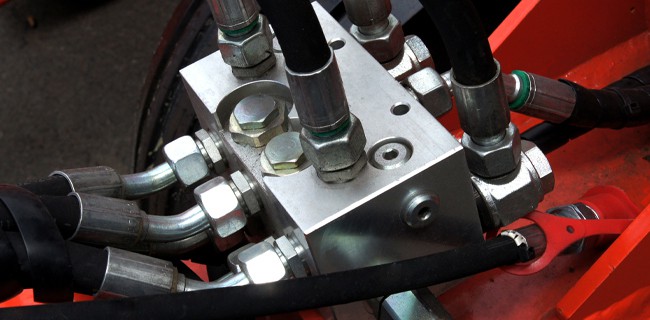

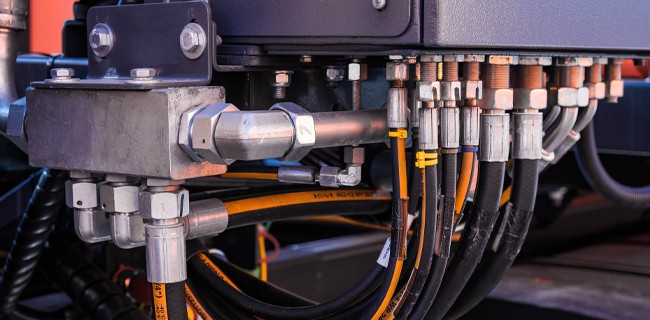

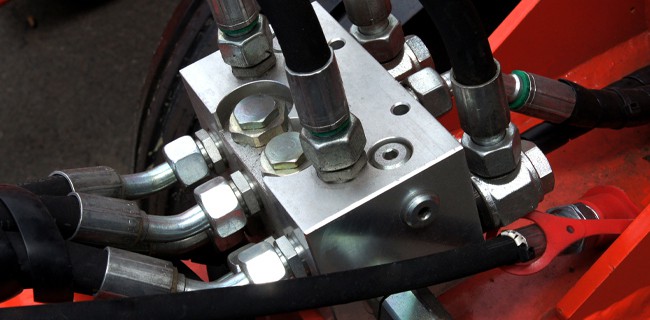

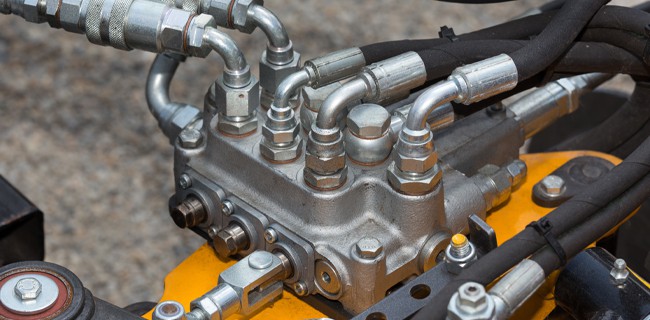

Hydraulic hoses on heavy equipment like bulldozers and excavators are exposed to harsh conditions, vibration, extreme cold or heat, chemicals and repeated strain (to name a few). When the hoses and fittings on that equipment aren’t routinely examined for wear and tear, your operation runs the risk of equipment failure. The mess, environmental damage, fines…

Read More